+1-617-398-7852

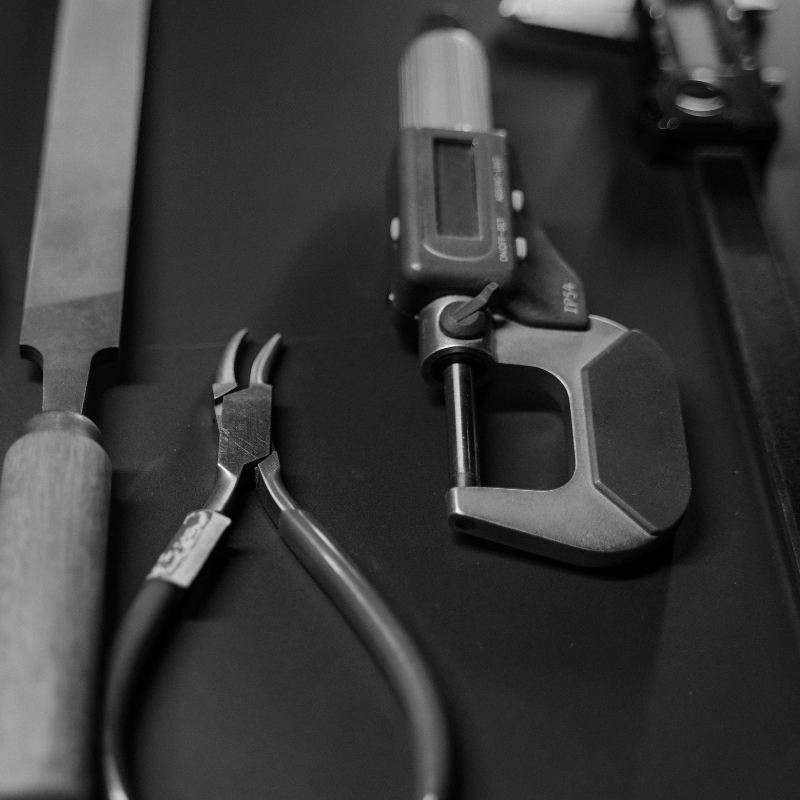

Beginner’s Guide to Micrometers: How to Get Accurate Measurements Every Time

Beginner’s Guide to Micrometers: How to Get Accurate Measurements Every Time

When it comes to precision measuring tools, few instruments are as reliable as the micrometer. Whether you’re new to machining, engineering, or metalworking, understanding how to properly use a micrometer is the first step to getting accurate results.

In this guide, we’ll cover the basics of micrometers, their types, how to read them, and practical tips to ensure precision measurement accuracy every time.

What is a Micrometer?

A micrometer, often referred to as a micrometer screw gauge, is a highly precise measuring instrument used to capture extremely small dimensions with unmatched accuracy. While tools like rulers and calipers are suitable for general measurements, micrometers are specifically engineered for tasks where even the slightest variation matters.

Unlike calipers, which typically measure in increments of 0.01 inches (0.1 mm), a micrometer can measure down to:

-

0.001 inches (one-thousandth of an inch)

-

0.01 millimeters (one-hundredth of a millimeter)

This level of precision makes micrometers indispensable in fields like machining, mechanical engineering, aerospace, automotive manufacturing, and quality control. Industries where tolerances are often measured in microns.

How a Micrometer Works

The micrometer’s precision comes from its ingenious use of a finely threaded screw mechanism, which converts rotational movement into very small, predictable linear motion. This is the principle that allows the tool to achieve such high accuracy.

-

Spindle and Anvil – The part being measured is placed between the fixed anvil and the movable spindle. The spindle advances or retracts when the user rotates the thimble.

-

Threaded Screw – Inside the micrometer, the spindle is connected to a precision-engineered screw. Because the screw’s threads are extremely fine, each full rotation of the thimble moves the spindle only a tiny distance often just 0.5 mm or 0.025 inches.

-

Thimble and Sleeve Scales – Measurements are read by aligning the graduated markings on the rotating thimble with those on the stationary sleeve (or barrel). This combination of scales allows users to easily interpret measurements down to thousandths of an inch or hundredths of a millimeter.

-

Ratchet or Friction Stop – Many micrometers include a ratchet mechanism or friction thimble to apply consistent measuring pressure. This prevents overtightening, which could distort both the part being measured and the accuracy of the reading.

Essentially, every turn of the thimble translates into a precisely controlled linear displacement of the spindle, which is then translated into a numerical measurement. This simple yet brilliant mechanical design is why micrometers remain one of the most reliable tools for ultra-precise measurements in machining, engineering, and quality inspection.

Types of Micrometers

Micrometers are not one-size-fits-all. Depending on what needs to be measured, whether its external size, internal diameter, or depth, there’s a specialized micrometer designed for the job. Each type follows the same screw-based principle but adapts its shape and components for different measurement tasks.

1. Outside Micrometer

-

Purpose: Measures the external dimensions of an object, such as diameter, thickness, or width.

-

How It Works: The workpiece is placed between the fixed anvil and the moving spindle. Rotating the thimble closes the spindle onto the part until the ratchet clicks, ensuring consistent pressure.

-

Common Uses: Checking shaft diameters, plate thickness, wire diameters, and small machined parts.

-

Variants: Standard, digital, and large-frame outside micrometers for bigger parts.

2. Inside Micrometer

-

Purpose: Measures the internal dimensions of holes, bores, and slots.

-

How It Works: Instead of an anvil, these micrometers use two opposing contacts (or extensions) that expand outward as the thimble is turned. The reading reflects the internal size being measured.

-

Common Uses: Inspecting the inside diameter of engine cylinders, pipe bores, or machined holes.

-

Variants: Can include interchangeable rods to cover a wider measuring range.

3. Depth Micrometer

-

Purpose: Measures the depth of holes, recesses, slots, or step features.

-

How It Works: Features a flat base that rests on the reference surface. The spindle extends downward as the thimble is rotated, contacting the bottom of the recess. The depth is read directly from the sleeve and thimble scales.

-

Common Uses: Measuring counterbore depths, slot depths, or the depth of drilled holes.

-

Variants: Often supplied with interchangeable rods to measure different depth ranges.

4. Specialty Micrometers

-

Purpose: Designed for highly specific measurements that standard micrometers cannot handle.

-

Examples Include:

-

Thread Micrometer – Measures the pitch diameter of screw threads.

-

Gear Tooth Micrometer – Measures the thickness of gear teeth at a specified point.

-

Tube Micrometer – Measures the thickness of tube walls without crushing them.

-

Blade Micrometer – Has thin, flat contacts for measuring narrow grooves or slots.

-

-

Common Uses: Precision inspection in aerospace, automotive, and specialized machining applications.

Parts of a Micrometer

Before using a micrometer, it’s essential to understand its key components. Each part plays a role in ensuring accuracy, ease of use, and repeatability.

1. Frame

-

The C-shaped body of the micrometer, designed to be rigid and stable.

-

Provides the structural backbone that holds all other parts in precise alignment.

-

Often made from steel or lightweight alloys with thermal stability to prevent expansion or contraction that could affect accuracy.

2. Anvil

-

A stationary, flat measuring surface located on one side of the frame.

-

Acts as the reference point against which the object is measured.

-

Precision-ground for flatness and durability, ensuring accurate contact.

3. Spindle

-

The movable measuring surface opposite the anvil.

-

Advances or retracts when the thimble is rotated, bringing it into contact with the workpiece.

-

Typically hardened and ground for wear resistance, as it’s the part that experiences the most movement.

4. Sleeve (Barrel)

-

The stationary outer cylinder of the micrometer.

-

Engraved with a linear scale, usually in millimeters or inches, which provides the main reference for measurement.

-

Works in combination with the rotating thimble to display precise readings.

5. Thimble

-

The rotating cylindrical component attached to the spindle screw.

-

Engraved with a secondary scale that aligns with the markings on the sleeve to indicate fractional values.

-

Allows controlled, fine adjustments for high-precision measurements.

6. Ratchet Stop (or Friction Thimble)

-

A small ratcheting mechanism at the end of the thimble.

-

Ensures that consistent measuring pressure is applied, preventing the user from overtightening, which could damage the part or give an inaccurate reading.

-

Essential for repeatability, especially in quality control environments.

How to Use a Micrometer

Using a micrometer requires patience and proper technique to ensure accurate results. Follow these steps:

1. Check Calibration

-

Before taking any measurements, gently close the spindle until it meets the anvil.

-

The reading should be exactly zero. If it’s not, adjust the micrometer using the supplied calibration wrench.

-

Skipping this step could introduce errors in every measurement you take.

2. Clean the Surfaces

-

Wipe both the measuring faces (anvil and spindle) and the workpiece with a clean, lint-free cloth.

-

Even tiny dust particles, oil, or burrs can throw off measurements by several microns.

-

In precision work, cleanliness is accuracy.

3. Insert the Object

-

Place the object between the anvil (fixed side) and the spindle (moving side).

-

Hold the micrometer by the insulated grip or frame—avoid touching the measuring faces with your fingers, as body heat can expand the metal slightly.

4. Turn the Thimble

-

Slowly rotate the thimble to move the spindle toward the workpiece.

-

Approach gently—never force the spindle, as this could damage both the tool and the part.

5. Use the Ratchet Stop (or Friction Thimble)

-

Once the spindle makes light contact with the object, switch to the ratchet stop.

-

Turn until it produces a few clicks. This applies a consistent, repeatable pressure, eliminating user error from overtightening.

6. Lock the Spindle (Optional)

-

Many micrometers include a locking lever or screw.

-

Use this if you want to “freeze” the measurement for easier reading or to move the micrometer away from the part before recording.

7. Read the Measurement

-

-

Analog Micrometer:

-

Look at the sleeve scale for the base reading (in mm or inches).

-

Then add the value from the thimble scale for the fractional measurement.

-

Some micrometers also include a vernier scale for even finer resolution.

-

-

Digital Micrometer:

-

Simply read the value displayed on the screen: fast and error-free.

-

-

When to Use a Micrometer

Micrometers are not everyday measuring tools like rulers or even calipers—they are reserved for situations where accuracy and repeatability are critical. Because they can measure down to thousandths of an inch (0.001") or hundredths of a millimeter (0.01 mm), they are the instrument of choice whenever tolerances are tight and mistakes could be costly.

1. When Extreme Precision is Required

-

If a part must fit perfectly with another component, even the smallest variation can cause failure.

-

For example, a shaft that’s only 0.002" too large might not fit into its bearing. A micrometer ensures these dimensions are controlled with microscopic accuracy.

2. When the Margin for Error is Minimal

-

Industries like aerospace, automotive, and medical devices often require tolerances measured in microns.

-

In these cases, a caliper may not provide enough resolution, but a micrometer can capture the difference between acceptable and defective parts.

3. During Quality Control and Inspection

-

Micrometers are heavily used in quality assurance labs to verify that manufactured parts match engineering specifications.

-

They are often part of statistical process control (SPC), where multiple measurements are taken to ensure production stays within tolerance.

4. When Measuring Small or Critical Features

-

Micrometers are ideal for tasks such as:

-

Measuring the thickness of thin materials like shims, foils, or sheet metal.

-

Checking the diameter of small shafts, wires, or pins.

-

Verifying the depth of precision slots or holes.

-

-

Their specialized variants (thread, gear, or tube micrometers) allow for accurate measurement of features that can’t be measured by other tools.

5. When Repeatability Matters

-

Consistent measurement is just as important as accuracy.

-

The ratchet or friction stop ensures the same pressure is applied each time, allowing multiple users to obtain nearly identical results on the same part.

How to Read a Micrometer Correctly

Reading a micrometer depends on whether you’re using a traditional analog model or a modern digital version. While digital micrometers are straightforward, analog ones require learning how to combine two (sometimes three) scales into one precise measurement.

1. Reading an Analog Micrometer

Analog micrometers typically provide readings in either inches (to the nearest 0.001") or millimeters (to the nearest 0.01 mm). To get the final measurement:

-

Read the Sleeve (Barrel) Scale

-

The sleeve shows the main scale.

-

On metric micrometers, each line usually equals 1 mm, with half-millimeter marks in between.

-

On inch micrometers, each line typically equals 0.025 inches.

-

Note the last visible line to determine the base value.

-

-

Read the Thimble Scale

-

The thimble rotates around the sleeve and has a series of fine graduations.

-

Each graduation represents a small increment (0.01 mm on metric models or 0.001 inches on inch models).

-

Find the line on the thimble that aligns exactly with the reference line on the sleeve.

-

-

(Optional) Read the Vernier Scale

-

Some micrometers include a vernier scale on the sleeve for even finer accuracy (down to 0.001 mm or 0.0001").

-

Identify which vernier mark lines up perfectly with a line on the thimble. Add this as the final digit.

-

-

Add the Values Together

-

Final measurement = Sleeve reading + Thimble reading (+ Vernier reading if present).

-

Example (Metric Micrometer):

-

Sleeve shows 12.5 mm

-

Thimble adds 0.23 mm

-

No vernier used

-

Final Reading = 12.73 mm

2. Reading a Digital Micrometer

-

Much simpler. Just place the object, close the spindle using the ratchet stop, and the measurement is shown instantly on the LCD screen.

-

Many models allow you to switch between inch and millimeter readings at the push of a button.

-

They also reduce human error and speed up measurement, making them ideal for beginners or high-volume inspection work.

Tips for Getting Accurate Measurements Every Time

Micrometers are capable of incredible precision, but small mistakes in handling or technique can lead to errors. To make sure every reading is trustworthy, keep these pro tips in mind:

1. Use the Ratchet Stop or Friction Thimble

-

Always rely on the ratchet stop (or friction thimble) instead of your fingers to close the spindle.

-

This ensures that the same amount of pressure is applied every time, preventing distortion of the part or inconsistent readings.

2. Keep Tools and Workpieces at Room Temperature

-

Metal expands when warm and contracts when cold. Even a slight temperature difference can change a measurement by several microns.

-

Avoid holding the micrometer’s measuring faces with bare hands for too long. Your body heat can transfer to the tool.

-

Ideally, let both the micrometer and workpiece acclimate to room temperature before measuring.

3. Check Calibration Regularly

-

Precision tools require routine calibration.

-

Use gauge blocks or standards to verify zero settings and accuracy at known dimensions.

-

If the micrometer doesn’t read correctly, recalibrate it before use to avoid systematic errors.

4. Avoid Overtightening

-

Applying too much force can do two things:

-

Damage the spindle or anvil faces, reducing the micrometer’s accuracy over time.

-

Distort the workpiece, especially if it’s thin-walled, soft, or delicate.

-

-

Always let the ratchet stop control the final pressure.

5. Practice Reading the Scales (for Analog Models)

-

Analog micrometers demand skill and patience. Misreading the sleeve or thimble by even one line means the measurement is off by 0.01 mm or 0.001".

-

Take time to practice combining readings until it becomes second nature.

-

Double-check your reading before recording it, especially when tolerances are tight.

6. Handle with Care

-

Micrometers are delicate instruments. Dropping them, overtightening the spindle, or storing them improperly can throw off accuracy.

-

Keep them clean, dry, and stored in their protective case when not in

Common Mistakes Beginners Make

Even though micrometers are straightforward once mastered, beginners often run into small but critical errors that can throw off accuracy. Being aware of these pitfalls will help you avoid them:

1. Measuring Dirty or Oily Surfaces

-

Dirt, dust, oil, or burrs on either the workpiece or the micrometer faces can add extra thickness to the reading.

-

This leads to inflated measurements that don’t reflect the actual size of the part.

-

Always wipe both the part and the tool with a clean, lint-free cloth before measuring.

2. Skipping Calibration Checks

-

Beginners often assume the micrometer is always correct. But over time, wear and small impacts can throw it out of calibration.

-

If the micrometer doesn’t read zero when fully closed, every measurement taken will be wrong.

-

Regularly verify calibration using gauge blocks or standards.

3. Misreading the Sleeve and Thimble

-

Reading an analog micrometer takes practice. It’s easy to confuse half-millimeter marks, skip a line, or misalign the thimble scale.

-

A single misread can lead to errors of 0.01 mm or 0.001", which is unacceptable in precision work.

-

Slow down, double-check, and if possible, compare against a digital micrometer until you gain confidence.

4. Holding the Micrometer Too Tightly

-

Micrometers are sensitive to thermal expansion. Holding the frame in your hand for too long can warm the metal, causing it to expand slightly.

-

This changes the distance between the spindle and anvil, leading to subtle measurement errors.

-

Always hold the micrometer by its insulated grip or the ratchet end, not the frame.

5. Applying Too Much Pressure

-

Beginners sometimes crank the thimble tightly, thinking it ensures accuracy.

-

In reality, this can flatten soft materials, damage the spindle faces, and give false readings.

-

Always rely on the ratchet stop or friction thimble for consistent, controlled pressure.

6. Measuring Immediately After Machining

-

-

Hot parts straight from a lathe or mill are still expanding due to heat. Measuring them right away gives inaccurate results.

-

Allow the part to cool to room temperature before using a micrometer.

-

Why Micrometers Are Essential for Precision Work

In the world of precision engineering, micrometers are more than just tools, they’re guardians of accuracy. From aerospace and automotive to medical device manufacturing, industries depend on micrometers to confirm that parts meet the tightest tolerances.

Even a seemingly minor error of 0.01 mm can:

-

Cause a bearing to seize.

-

Lead to gaps in an assembly.

-

Waste costly materials.

-

Require expensive rework or even scrap entire production runs.

That’s why micrometers are considered a gold standard for dimensional accuracy. They bridge the gap between design specifications and real-world parts, ensuring components not only fit but also perform safely and reliably.

By mastering micrometer use, you’re not just learning a measurement technique, you’re building a foundation in discipline, consistency, and precision thinking that carries over to every aspect of professional engineering and machining.

Final Thoughts

The micrometer remains one of the most trusted, accurate, and reliable measuring instruments available. While it may look simple, its effectiveness depends entirely on the operator’s technique. With careful handling and consistent practice, even beginners can achieve laboratory-level precision.

Key Takeaway:

-

Calibrate regularly – trust starts with zero.

-

Handle carefully – treat it like the precision instrument it is.

-

Use the ratchet stop – let the tool control the pressure, not your hand.

-

Practice consistently – mastery comes from repetition.

By applying these habits, you’ll ensure that every measurement is not just a number, but a guarantee of quality. Whether you’re checking the diameter of a tiny pin or the thickness of a machined plate, the micrometer equips you with the confidence that your work meets the highest standards.